REGULARS

FEATURES

INDUSTRY NEWS

R&D

TOMATO-POTATO PSYLLID FEATURE

CONTENTS

18

24

28

05

06

32

Editorial

Messages from the Chairman and CEO

Regional updates

08

34

Hort Connections 2017: Speaker line-up announced

Young Potato People

18

28

Young grower profile: Chris Gallagher

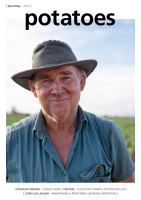

Grower profile: Stephen Osborn

09

20

22

23

24

27

30

31

10

11

12

14

15

16

17

The National Potato Levy at work

Potato extension activities aim to address important

industry issues

Ask the industry

Gaining an understanding of Verticillium wilt

Student profiles: Next generation of potato research

Plant-parasitic and free-living nematodes:

What are the differences?

New initiative to provide a fair go for workers and growers

Introducing new potato varieties to Canada through

an open house

Tomato-potato psyllid: A destructive potato pest

Supporting Australia's potato growers during an incursion

The Front Line: Tomato-potato psyllid detection

Neighbours across the ditch reflect on

tomato-potato psyllid

Responding to an exotic pest incursion

Using an integrated pest management strategy to

manage psyllids

Economic update: The economic impacts of

tomato-potato psyllid overseas

A leader in the design, manufacture & supply of

specialised agricultural machinery

DOBMAC

AGRICULTURAL MACHINERY

Carefully calibrates, sorts and weighs up to 30 potatoes per second

Email:

dobmac@dobmac.com.au• Website:

www.dobmac.com.auAn ingenious system arranges the potatoes one after the

other smoothly and at high speed. The software optimises

the sorting rate automatically. A surge hopper installed

above the aligner absorbs any variation in the feed stream.

Electric controls enclosed in a sealed cabinet.

Control computer with factory-set sorting software ready for

production.Waterproof and washable monitor, keyboard,

and mouse. Assembly on the left- or right-hand side

of the machine.

A nozzle system blows the potatoes towards the

various outlets allocated with great precision. The potatoes

fall on soft materials, which ensure a smooth landing. The

casing is equipped with washable soundproof panels and

large doors, which make it easier to clean.

Two three-way conveyor belts for

receiving and distributing the six

grades. Custom length according to

requirements.

Aligner

Control Interface

6 Outlets

Outlet Belts

Handling Innovation

• Efficient & gentle vegetable handling

• Belt widths up to 2.4m wide

• Wide range of cleaning tables

• Complete turn key solutions

• Heavy duty construction

• Mobile graders

• Field transfer trailers

• Sizing and sorting

• Box & big bag fillers

• Box tippers

• Potato & Carrot Washing

• Brassica trimming & grading equipment

Efficient & gentle vegetable handling

For

washed &

unwashed

potatoes

Heavy duty

complete

turn key

solutions

High-performance

intelligent optical

sorter