Veg industry SARP reports

15 June 2025

Mammoth edition of Vegetables Australia released!

20 September 2021Drip is now widely accepted as an efficient and cost-effective way to irrigate your crops, but how do you tell the difference between brands and models? In this column, Netafim Product Manager Wayne Ingram discusses non-pressure compensating (NPC) emitters, which are very commonly used in Thin Wall Dripline.

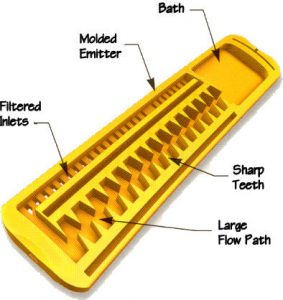

Emitter structure

Water passes through the emitter filter and enters the flow path/labyrinth. The sharp teeth keep fine particles in suspension and enable them to exit the emitter. A hole or flap above the bath is the final exit point for the water.

Clog resistance

The greatest concern for most growers is their drippers clogging. Assuming quality design, filtration, and installation is all in place, then it is largely up to the dripper to perform reliably and stay clean.

Clog resistance is a function of these parameters, all of which are measurable.

- Emitter Filtration Area (mm²): Bigger is better, like a suction strainer on a pump.

- Labyrinth Length (mm): Shorter is better, less opportunity for small particles to settle.

- Labyrinth Depth (mm): Deeper is better, allows larger particles to pass through.

- Labyrinth Width (mm): Wider is better, allows larger particles to pass through.

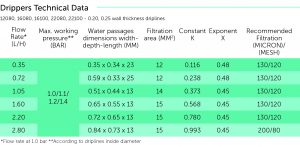

To evaluate one brand of emitter against another, this format Table should be used as a guide. Insist on your irrigation supplier providing the numbers shown here.

Accuracy and uniformity

Non-pressure compensating emitters will discharge a higher flow when more pressure is introduced into the lateral.

The equation for Emitter Flow is: Q = K*P^x, where:

K = constant (see table above).

P = pressure expressed in metres head.

x = Flow Exponent (see table above; lower is better).

For the dripper/emitter in the table above: if the pressure is increased by 100 per cent, the flow only increases 37 per cent (using Exponent x = 0.45).

Other emitters with an exponent of 0.50 will have a 50 per cent increase in discharge, with 100 per cent increase in pressure.

What this means is an emitter with a lower flow exponent will have better uniformity if the lateral length is the same compared with an emitter with a higher flow exponent. Likewise, the grower can have a longer lateral – all other things being equal.

Therefore, with a lower flow exponent – all things being equal – the grower can expect higher uniformity of irrigation within the irrigated block. High uniformity is achieved with a low flow variation within the block.

Excellent uniformity would be a block that has 10 per cent (or less) flow variation (FV).

This 10 per cent FV means that the highest output emitter discharges five per cent more than the average flow emitter, and conversely the lowest output emitter discharges five per cent less than the average flow emitter.

When reading an irrigation plan, this could be written as FV = 10% (-5%, +5%).

It is thought that a one per cent decrease in flow variation equates to a one per cent decrease in yield.

cent decrease in yield.

Quality is key

Driplines in the market should at the very least comply with ISO 9261 – Agricultural Irrigation Equipment Emitters and Emitting Pipe – Specification and Test Methods.

This provides peace of mind to the grower that the dripline they purchase meets this International Standard.

Find out more: Please visit the Netafim website.