Advocating for vegetable growers to achieve long-term outcomes

3 June 2020

Capsicum: The feel-good crunch

3 June 2020In 2017, a strategic levy investment was established to support the vegetable industry in adopting precision agriculture technologies. Over the last three years, the project team has worked with vegetable industry members to develop data packages, which are being used to help growers boost yield. AUSVEG Communications Officer Sophie Burge speaks to agronomists Stuart Grigg and Kaushal Gunasekara about their involvement in the project.

A strategic levy investment under the Hort Innovation Vegetable Fund, Adoption of precision systems technologies in vegetable production (VG16009) has been working with growers across Australia to implement the following precision agriculture technologies, and assess their potential in vegetable systems, including:

- Different soil sensing technologies. e.g. EM38, Veris®, SISTM.

- Crop sensing imagery for various applications.

- Strategic soil and plant sampling (including grid mapped soil sampling).

- Yield prediction from remote sensing imagery.

- Yield monitors.

- Variable rate applications.

The Queensland Department of Agriculture and Fisheries (DAF, QLD) has led the project, with a number of collaborators across Australia including the University of New England, Tasmanian Institute of Agriculture, Harvest Moon, Primary Industries and Regions South Australia, vegetablesWA and the Society of Precision Agriculture Australia (SPAA).

Investigating precision ag

One vegetable industry member who has benefited from involvement in this project is Stuart Grigg from Stuart Grigg Ag-Hort Consulting. Stuart is an independent agronomist based in Victoria who has worked with vegetable growing operation, Fresh Select, at its Werribee South headquarters for the past 10 years. Stuart’s role involves crop scheduling, variety selection, pest and disease identification, nutrient use with a focus on sustainability and new developments in the agronomy sector.

Stuart explains why he decided to take part in this project.

“I was already going down the path of investigating precision agriculture and seeing where it could fit within the horticulture sector,” he says.

“This project allowed me to be involved in the investigation of these technologies on a more precise scale and prove exactly where the actual benefits exist for the growers I’m working with.”

Stuart explored a range of on-farm precision ag activities including Electromagnetic induction (commonly referred to as EM) and soil grid mapping. EM detects soil electrical conductivity, and is a cost-effective option for detecting spatial differences in moisture, clay content and salt levels in soil.

“The focus for me initially was in soil grid mapping and actually being able to understand where nutritionally-different areas of the same paddock exist, which compromises paddock and crop uniformity. EM Surveying looked at different soil types and potential salinity issues within those paddocks,” Stuart says.

Taking to the sky

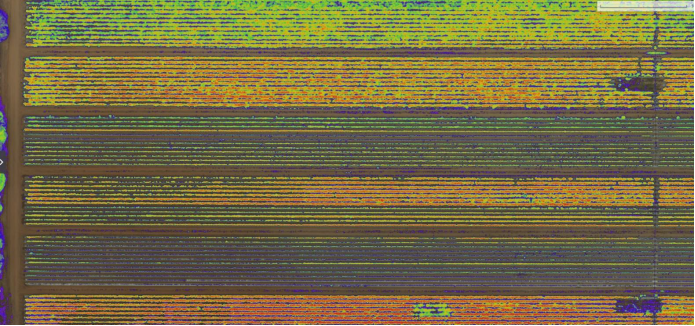

Another aspect of this project that piqued Stuart’s interest was the use of drone imagery. Using drone technology means that Normalised Difference Vegetation Index (NDVI) and the near infrared (NIR) imagery is captured, as Stuart explains.

“Now we can start scanning crops from the air and actually look at the variability of the crops. We can see the interactions between the soil, the soil characteristics, and the soil issues that we’ve identified by the mapping, as well as how the crops the actually respond to that soil issue, soil type or nutrient status that we’ve identified from our soil tests,” Stuart says.

The next part of the drone technology was to run plant counts over the crops.

“One of our focuses at Fresh Select is to understand the amount of produce that’s expected to come into the business’ warehouse on a weekly and monthly basis,” Stuart says.

“Putting a drone over the crop means we record an exact number of plants, plus or minus two per cent in the field. So, we can fly a crop two or three times after planting and get a really good idea of the number of plants that have actually established in that field, as well as look for variability in the crop. We can then start to make pretty good yield estimations.

“These numbers give Fresh Select more information and clarity around expected volumes the business will receive in one-or two-months’ time, which allows the sales and marketing team to make much more informed decisions.”

Drone focus: Austchilli

Kaushal Gunasekara is the Horticultural Technical Agronomist at Austchilli, a chilli growing operation based in Bundaberg, Queensland.

Austchilli began precision ag practices in the mid-1990s and implemented GPS-guided control traffic operations about a decade ago. The operation began using automated irrigation systems around three years ago and followed this with using drones from 2018.

“We had several rounds of training, starting with the legislative procedures and the legal aspect of drone operation on farms,” Kaushal says.

As part of his involvement in the DAF, QLD-facilitated project, Kaushal also attended a grower study tour of South Australia, Victoria and Tasmania in 2019. Held from 4-11 September, the levy-funded tour provided participants with the opportunity to visit case study farms and share experiences in getting the most out of precision ag technologies for their vegetable growing business.

“It was one of the most important experiences in my life as an agronomist and we learnt a lot as an organisation,” Kaushal says.

“We saw how controlled traffic operations are taking place in different farming systems and how the variable rate of irrigation takes place.”

Networking was also a highlight of the precision ag tour.

“We had a great opportunity to create a network with fellow agronomists and growers around the country, who are involved in precision agriculture activities,” Kaushal says.

Kaushal explains why Austchilli explored precision ag technologies and discusses its importance in the business.

“The main driver is to increase input productivity. With every aspect of precision agriculture, we are focusing on improving our production, and our yield and quantity and quality of the yield, with minimising the inputs,” he says.

“Being in a very sensitive region in Australia, near the Great Barrier Reef, it’s very important. One of our main focuses is to optimise our fertiliser and spraying programs without negatively contributing to the environment.”

Grower advice

Kaushal has tips for vegetable growers who are looking to enter the precision ag space.

“The most important thing is to do thorough research before you select a precision agriculture tool in your farming system,” he says.

“Every operation is different. For instance, a grower who is doing trickle irrigation is different to someone who is doing overhead irrigation. Or someone can have a large-scale field crop production, whereas someone else has fairly small land that is protected agriculture.

“Doing your research before you go into the precision agriculture operations will help to save you a lot of money. Because if you make a wrong decision, then you have to go back to correct it, and you won’t be able to receive the maximum benefit.”

“Projects like this help growers, and if you do your homework properly, you’ll be able to improve your productivity and profitability.”

Find out more

Readers can listen to Stuart Grigg and Kaushal Gunasekara speak about their experiences on InfoVeg Radio. The podcast can be found here.

For further information about this project, please contact DAF, QLD Senior Development Horticulturist Julie O’Halloran on 0409 054 263 or at julie.ohalloran@daf.qld.gov.au.

This project has been funded by Hort Innovation using the vegetable research and development levy and contributions from the Australian Government.

Project Number: VG16009

This article first appeared in the winter 2020 edition of Vegetables Australia. Click here to read the full publication.