Implementation Plan for Increasing Children’s Vegetable Intake

12 June 2017What is compost worth? Using compost in Australian vegetable systems

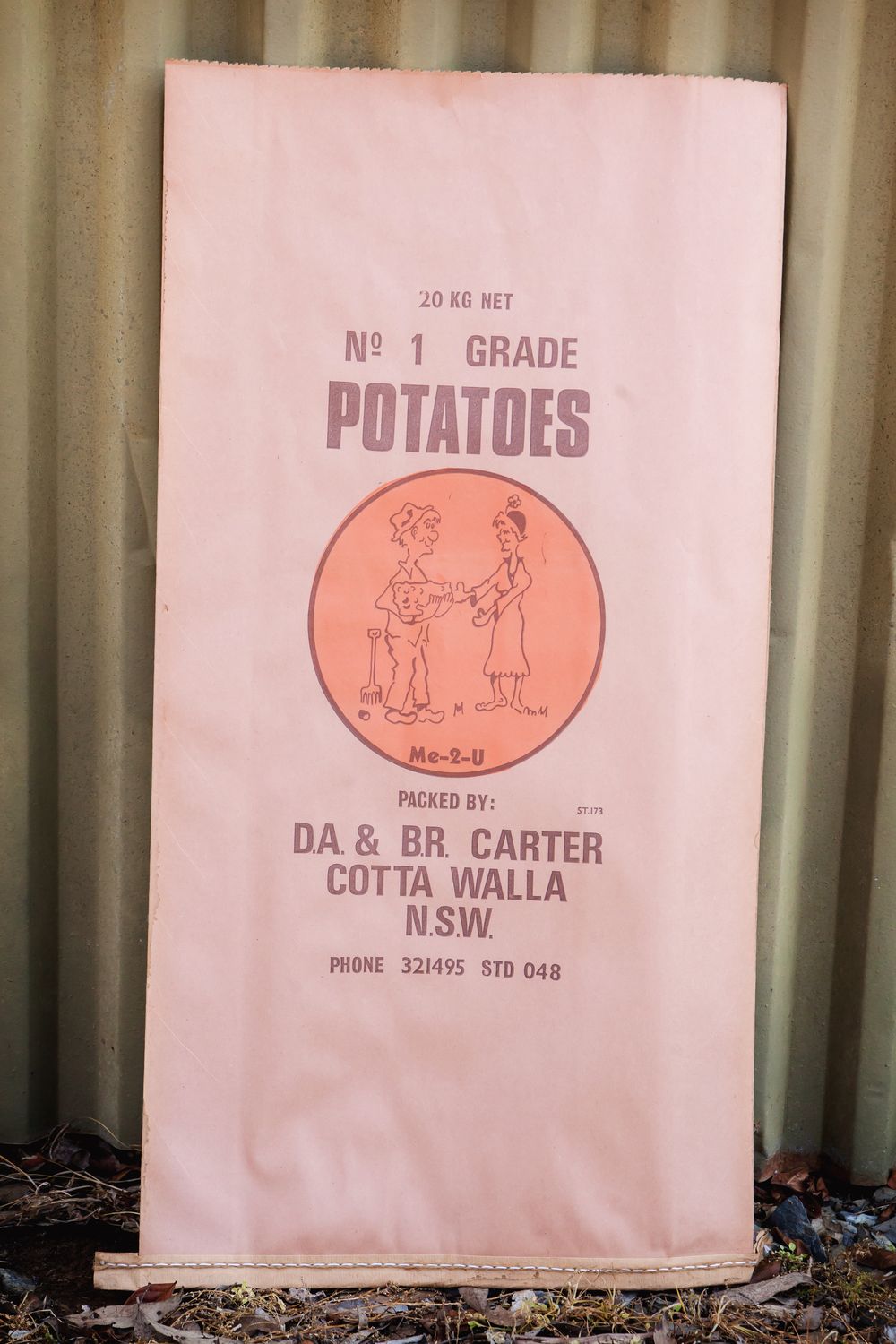

20 June 2017After 60 years of working in the Australian potato industry, Crookwell Potato Association mini-tuber producer David Carter retired in 2017. In this article from the June/July 2017 edition of Potatoes Australia, David spoke to AUSVEG, reflecting on his time in the industry and his love for producing premium mini-tubers for seed growers in New South Wales.

Fast facts

Name: David Carter

Location: Crookwell, NSW

Works: Cottle Wolly

Grows: Potatoes

David Carter’s potato growing journey began in 1957, after watching his father employ share farmers to manage the family’s potato crop.

Over 30 years later, in November 1988, David’s career took a different turn when he began to grow mini-tubers for the Crookwell Potato Association. While he continued to grow potatoes in the field, mini-tuber production took over completely in 2003, fuelled by an interest in pushing the boundaries and developing new ideas.

“I travelled overseas in 1964 for three months and studied potatoes in the United States and United Kingdom, and then my wife Barbara and I went over to Holland and studied their potato production in the ‘80s,” David says.

“We’ve always been interested in mechanising as well; we introduced half tonne bins, basic harvesters and irrigation. It’s always been a bit of challenge to make things more efficient, keep it operating and make it easier for the growers.”

David was also a state representative on many potato seed boards over the years, and contributed to the formation of the Australian National Standard for Certification of Australian Seed Potatoes.

Mini-tuber process

David explains that mini-tuber production is a very time-consuming exercise, which requires a lot of patience. However, the results can be very rewarding: at one stage, David was growing up to 30 varieties in three polyhouses and subsequently produced up to 60,000 mini-tubers.

“We buy the plant material from a laboratory facility such as ViCSPA. Then we plant them out in growth medium or potting mix and grow them for about 12 weeks for each plant,” he says.

“Depending on the variety, the plant material will produce somewhere between 1.5 potatoes per plant at worst, and up to about nine, at best. The mini-tubers range in size from a golf ball down to a marble.

“The technical term is limited generation, so we’re introducing new material every year into the system so any virus that may occur in later generation crops can be replaced quickly. Also, it’s very quick for introducing new varieties – it’s probably 10 times faster now.”

David’s mini-tuber facility is accredited by ViCSPA and must comply with all of its inspections and regulations to ensure the conditions of seed certification standards are being met.

“The name of the game is to supply certified seed growers with clean material to begin with,” he says.

An evolving industry

David has experienced many changes in potato production over six decades, including the introduction of plant variety controlled lines resulting in outlet control of these varieties. When irrigation was introduced into seed production, it also contributed significantly to increasing yield and making the production process more economically viable.

However, there have been plenty of challenges and learning curves along the way.

“Keeping our facilities aphid or thrip-proof is always a challenge – we’ve got fine mesh up and that’s probably our most difficult part,” David says.

“We also started off doing what was recommended, which was block spraying where you just sprayed pretty regularly in the glasshouses. We found that it wasn’t necessary and, if anything, doing more harm than good.

“We’ve reduced chemical use radically in the houses – almost to the extent of using one chemical a year. That’s dependent on the facility being up to standard, not allowing insects in and keeping quarantine practices in place. For example, using a foot bath and wearing clean clothes, a clean hat and having clean hands.

“We’ve been able to improve that using a lot less chemicals, which is so much better.”

"The important thing is to enjoy it. I think that applies to all jobs – if you really enjoy it and do it well, you’ll get a lot of satisfaction from it and you’ll continue to do it for a long while."

Career highlights

The development of Technitubers, which occurred over a period of five years during the 2000s, was a very exciting time for David and Barbara.

Developed in Australia, Technitubers are produced aeroponically (growing in an air environment), and they’re very small – about the size of a pea to a marble.

“It involves sequential harvesting where you continually take potatoes off the plant, so one plant might produce 40 or 60 little tubers. It just reduced the cost tremendously,” David explains.

“It’s a relatively small market, so it was brought into China and India, and became very big in both countries. We got involved in the very early part of that with growth trials. Barbara and I travelled around Australia, planting trial plots for Technitubers and we built a facility at home. It was a real challenge and very exciting work because you’re dealing with overseas companies and people investing in it. We learnt a lot in that period.

“We were lucky enough to see the production system open in Kunming, China, which was very exciting and very different to Australia.”

Next phase

Although David is retiring from supplying mini-tubers to Crookwell, he is intent on continuing his association with the potato industry and working with the younger generation.

“You can get very set in your own ways as you get older and you probably get a bit more conservative. That’s where I think the youth coming through provides some balance. My aim is to work with the state and with our local board, but encourage younger ones to take it over gradually.”

As for David’s advice to his peers in the industry, it is simple: “The important thing is to enjoy it. I think that applies to all jobs – if you really enjoy it and do it well, you’ll get a lot of satisfaction from it and you’ll continue to do it for a long while.”

This grower profile first appeared in the leading magazine for the Australian potato industry, Potatoes Australia. If you’d like to subscribe to receive a new edition of Potatoes Australia in your mailbox every two months, use our online subscription form!

Photography credit: Kim Shirley