Grower embraces benchmarking for success

28 May 2025

Big growth from baby leaves after 50 years of Hussey & Co

28 May 2025VegNET Tasmania Regional Update

West Pine is a diversified agri-food business based in Penguin, North West Tasmania, founded in 2018 by Rob Arvier and Mark Reeves. West Pine has diversified differently to most vegetable farming businesses in Tasmania. Alongside their vegetable crops, they run livestock, grow cereal and fodder crops and provide agribusiness advisory services.

This highly diversified model not only offsets the risk involved with primary production but, as Rob emphasises, “allows us to put our advisory skills into the primary production space with our farm business informing how our advisory skills can be applied in practice”.

In late 2024, the West Pine team expanded with Emily Roberts joining with over two and a half years’ experience in carbon accounting in the corporate sector, helping businesses to quantifytheir carbon emissions in alignment with the current Greenhouse Gas Protocol.1

New to the horticulture sector, Emily’s curiosity and accounting mindset prompted her to question why and how many onions were left in the paddock after the 2024/25 harvest. Drawing on the true cost accounting approach, which looks to measure hidden or externalised costs involved in food production,2 Emily explored the volume of leftover onions and the reasons behind it.

Measuring onion crop loss at harvest

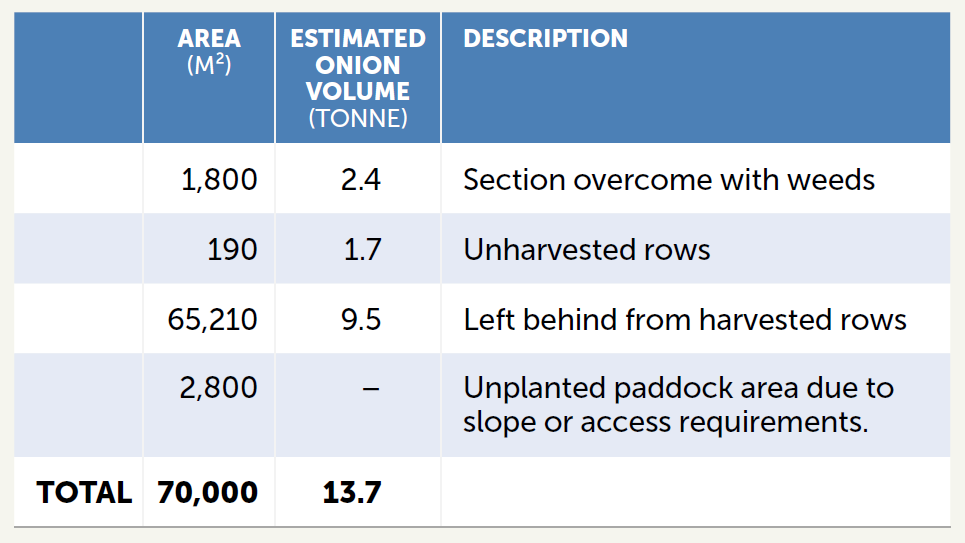

Following Emily’s deep dive into data crunching, West Pine measured an estimated 13.5 tonnes of brown onions left in the 7ha paddock after harvest3 – this equates to approximately 14 one-tonne bins.

They measured the loss by taking random samples from 5m x 5m plots throughout the harvested area and 1m x 1m plots in weedy and unharvested rows. Approximate measurements of length and number of weedy/unharvested row as well as the unplanted sections were then taken to extrapolate their samples to the applicable areas.

TABLE 1:

West Pine evaluation of onion crop loss at harvest from a 7ha paddock for this season, 2024-254

While some crop loss is unavoidable, the data collected from this season’s harvest has enabled the West Pine team to look more closely into the reasons why and consider opportunities to improve yield in future seasons.

Rob notes that “you can’t manage what you’re not measuring”, drawing on the well-known quote from business management expert Peter Drucker.

Challenges contributing to the volume of crop loss:

- Paddock topography (slopes) and soil conditions, especially structure.

- Machinery type required to access different areas (i.e. unable to plant or unharvested due to steepness).

- Time restraints on intake due to varying reasons such as seasonal variations, pack shed capacity, market demand.

- Differing priorities of markets in size and quality of onions and how this pressure is applied down the supply chain.

Opportunities for future onion crop yield improvement by avoiding losses in the paddock:

- Utilising different paddocks to address topography barriers, plant with crop management and harvest in mind.

- Select paddocks with good soil structure, no compaction.

- Improved weed management.

- Review current rotations, check LISTmap for further paddock information (soil type, land capability, elevation/slope) and implement a whole of paddock plan to understand potential machinery restraints for different types of machinery for crop management and harvest.

- Avoid growing onions after other root crops that cause a decline in soil structure.

These opportunities would likely reduce otherwise wasted inputs on planting, spraying etc, to only include areas that can be fully serviced for the whole of crop life.

Given that productive crops have low emissions, West Pine calculated the emissions intensity of their previous season red onion crop (cradle to farm gate) to be 130 grams of CO₂-e per kilogram.5 Being able to measure and identify property level data per crop is an ideal state for carbon emission reporting, however the tools and support for this are not yet widely available.6

Rob notes that “you can’t manage what you’re not measuring”, drawing on the well-known quote from business management expert Peter Drucker. Identifying, categorising and quantifying costs and benefits at the farm level, farmers can make more informed decisions, clearly identify risks and rewards in the supply chain and better maximise their reward for input and effort.

Where to from here?

From an economic and environmental perspective, every year in Australia 7.6 million tonnes of food is not used. In the horticultural supply chain, an estimated 23.7 percent (908,403 tonnes) of food loss occurs during primary production and 10.7 percent (409,744 tonnes) during the processing stage.7

With farm-level emissions reporting and global transparency expectations on the horizon, West Pine is proactively preparing for future requirements. Through initiatives like the Onion Life Cycle Assessment project (Hort Innovation funded project VN23001), they are working to assess and reduce their costs, improve marketable yield and reduce inputs and environmental impact while strengthening their position for export market access and price premiums.

Tasmania’s horticultural sector is distinct from most mainland regions, with a strong presence of processors and packers, and varying grower arrangements involving direct contracts, land leasing or joint ventures with larger operations and packers. Many packing operations also manage their own farms, adding layers of complexity to addressing crop loss both on-farm and during processing.

West Pine see the need for a holistic, industry-wide approach to reducing crop loss and food waste, with a focus on improving crop recovery during production, harvesting, and packing— where cost-effective gains can be made by addressing issues like topography, equipment, soil and crop management, handling and grading damage. They are optimistic about the potential for collaboration and action across the supply chain, noting, “from cradle to gate (and beyond), there’s so much opportunity for improvement”.

FIND OUT MORE

Contact Prudence Rothwell, VegNET Tasmania Regional Support Officer, RMCG on 0477 182 408 prudencer@rmcg.com.au who can link you with relevant Hort Innovation Projects (VN23001 & MT22009) that aim to increase vegetable grower’s insights into production costs on their farm, quantify and benchmark costs involved with onion production and carbon emissions from cradle to gate.

Contact Emily Roberts, Carbon Accounting Advisor, West Pine emily@westpine.com.au to access their 2024 carbon assessment report.

Contact Donna Lucas, RMCG at donnal@rmcg.com.au to find out how to benefit from benchmarking for vegetables an onions and lifecycle assessments of emission for onion crops.

References

02. The Economics of Ecosystems and Biodiversity (TEEB),True Cost Accounting For Food Systems: Redefining Value To Transform Decision-making, access: teebweb.org/wpcontent/uploads/2021/09/TechnicalBriefingNote.pdf

3-4. West Pine, March 2025 linkedin.com/posts/westpineag_sustainablefarming-foodwasteonionharvest-activity-7305725737498464256-2Dw7 (LinkedIn Post).

5. West Pine, April 2025 linkedin.com/posts/westpineag_carbon-assessment-report-2024-sneak-peak-activity-7313697323459436546-R4ra (LinkedIn Post).

6. Primary Industries Climate Challenges Centre 2023, Greenhouse Accounting Frameworks (GAF) for Australian Primary Industries, access: piccc.org.au/resources/Tools

7. End Food Waste Australia (2024) The sector action plan for food waste reduction, access: endfoodwaste.com.au/wp-content/uploads/2024/03/Technical-Report_Horticulture-Sector-Action-Plan.pdf.

8. West Pine, March 2025 linkedin.com/posts/westpineag_sustainablefarming-foodwasteonionharvest-activity-7305725737498464256-2Dw7 (LinkedIn Post).