Australian vegetable export overview Jan-Aug 2025

8 December 2025Plus One Serve launches Retail Setting Action Plan

9 December 2025A group of Australian vegetable growers and industry members travelled to New Zealand’s North Island from 24–29 August 2025, to learn about production systems, technologies, and management practices used in NZ horticultural industries. This included agronomic considerations such as crop management, pest, disease and weed management, resource efficiencies including labour and succession planning, as well as broader operational and environmental aspects. What we discovered was that while our trans-Tasman neighbours face remarkably similar challenges, their approaches to solving them offered fresh perspectives worth bringing home.

2025 PROGRAM

Sunday, 24 August

Travel to Wellington, New Zealand

Monday, 25 August

Horowhenua, Opiki

- Lewis Farms

- Moleta’s Potatoes

Tuesday, 26 August

- MPI – Airport biosecurity behind the scenes

- Moore Wilsons – Independent retailer

- Hot Lime Labs

- Vegetables NZ – Dinner

Wednesday, 27 August

Wellington

- New Zealand Horticulture Conference

- New Zealand Horticulture Gala Dinner

Thursday, 28 August

Hawkes Bay

- Fly to Hawkes Bay

- Apatu Farms

- LandWISE Inc. – Research farm

Friday 29 August

- Bayley Produce

- Fly home

DAY ONE

Small-scale innovation in the Horowhenua

After a long day of travel from across Australia on Sunday, and for some a late arrival in Wellington, the group headed off after breakfast. The first stop was Lewis Farms, a fourth-generation family operation growing asparagus and berries located in the temperate Horowhenua region, 90 minutes north of Wellington. Several varieties of asparagus are grown across a number of blocks within 20kms of the Packhouse. The geographical spread of crops provides some protection against isolated climatic events. The farm has adapted to changing markets since losing export opportunities to Japan and local cannery closures, now focusing on supplying domestic markets. Lewis Farms expanded to grow berries hydroponically in poly-tunnels and also runs a farm shop.

Plastic tunnels are used in the asparagus crops to warm soil and capture early market advantages, a technique learned from Europe. These tunnels are lifted each day to harvest the asparagus spears. Yes, lifting these tunnels daily across kilometres of crop is labour-intensive, but this is justified by the financial returns. Lewis Farms’ rely on the Pacific Island RSE scheme (similar to the PALM scheme in Australia) for harvesting. Workforce availability emerged as a challenge across many operations visited during the tour. The plastic tunnels presented some challenges for weed management as residual herbicides require moisture to be effective, and there is not always sufficient moisture for this to be effective under the tunnels.

The farm has developed its own asparagus grading and packing/tying machine using image analysis rather than weight-based methods.

Later that day at Moleta’s Potatoes, a small, family farm in Opiki that has been growing fresh and processing potatoes for more than 20 years, the group was surprised by the low incidence of soilborne pests and diseases. The secret? A long (nine–10 year) crop rotation program. The farm uses conventional equipment with minimal automation. Storage facilities enable the farm to extend sales throughout the year, with the previous year’s crop only being fully sold by the time of the study tour. Seed potatoes are sourced from the South Island, grown below a specific latitude to ensure quality. Potato production has declined in the region over recent years, largely replaced by dairy farming. Several factors have contributed to this shift, including change in demand for fresh potatoes, increased consumption of processed potato products, and improved storage technologies that have altered market dynamics.

Also contributing to this decline was the arrival of tomato potato psyllid and zebra chip, with yield losses of up to 25 percent and increased management costs reported. The operation demonstrated that sometimes keeping things simple –basic equipment, low input costs, and disciplined rotations – can maintain profitability without expansion. Notably, the grower expressed no interest in increasing farm size, preferring to optimise current operations.

DAY TWO

Biosecurity and innovation

Tuesday morning’s behind-the-scenes tour of MPI’s airport biosecurity operations was a real eye-opener. The Ministry for Primary Industries (MPI) is responsible for New Zealand’s biosecurity system, which protects the country’s agricultural industry and natural environment from harmful pests and diseases. MPI staff demonstrated the multi-layered approach used to identify and intercept potential biosecurity threats. This system combines passenger declarations, advanced screening technology including AI bots, trained detector dogs, and biosecurity officers. The screening focuses on high-risk items such as certain foods, animal products, and used outdoor equipment that could introduce biosecurity threats into the country. The tour reinforced understanding that biosecurity efforts directly support horticulture and farming sectors. This connection between border protection and on-farm productivity helped participants appreciate the critical role biosecurity plays in maintaining New Zealand’s competitive advantage in agricultural production and protecting its unique natural environment.

After lunch, the group informally toured Moore Wilson’s Wellington store. Tour participants naturally gravitated toward crops on the shelves that they grow, comparing displayed products with their own experiences in Australia. Growers took particular notice of the quality of produce on display, questioned stock rotation, prices (appeared expensive compared with Australian retail), layout and presentation. The visit sparked valuable discussion about retail standards and how industry professionals scrutinise environments differently than typical shoppers.

That afternoon at Hot Lime Labs, the group learned about novel research developing into commercial opportunities—a system capturing CO₂ from waste wood (and, in future, waste biomass) for greenhouse enrichment while generating heat. The environmental benefits are clear, though the capital costs and fuel supply requirements raised questions about transferability to Australia. Still, for greenhouse operations in the right circumstances, this could be game-changing.

To conclude the day, the group joined the NZ vegetable growers for dinner – a great opportunity to make new connections and catch up with old ones.

DAY THREE

New Zealand Horticulture Conference connections

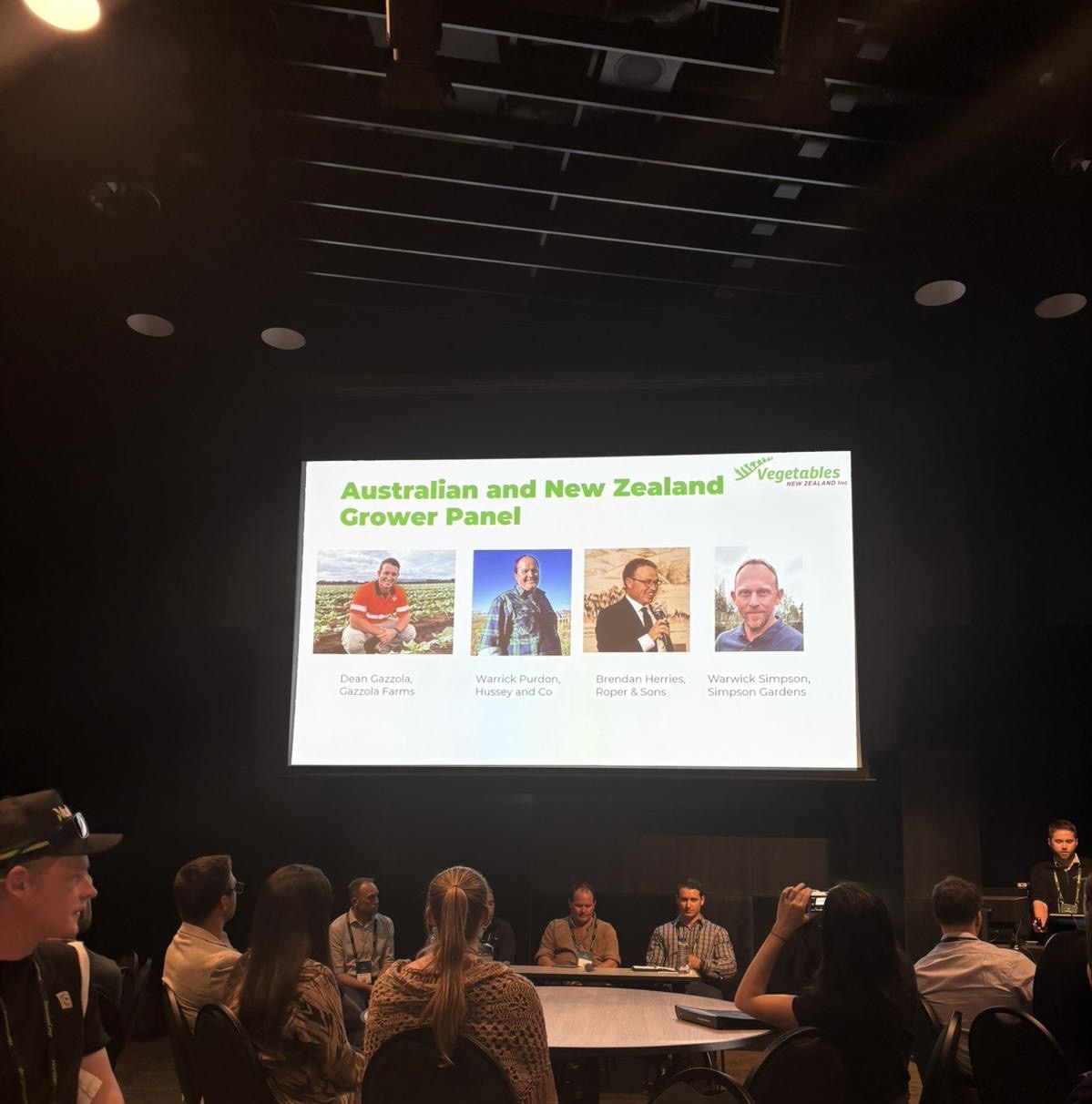

The New Zealand Horticulture Conference provided valuable opportunities for networking and knowledge exchange. Two Australian growers joined panel discussions, comparing opportunities and challenges across countries. The Carbon Robotics laser weeder generated particular interest for cost savings and reduced herbicide use. Inspirational presentations stood out, especially Tamati Ellison’s session on motivation and leadership, and Kenny Lau’s economic outlook that challenged assumptions about consumer perceptions—insights considered transferable to Australia. The group also heard about operational and environmental challenges faced by New Zealand counterparts, finding many issues similar to home including pest management, workforce challenges, and resource efficiency. Workforce solutions, particularly through labour schemes like RSE, and HR management systems emerged as a strong conference theme.

DAY FOUR

Large-scale operations in Hawke’s Bay

After an early start and minor flight delay, we arrived in Hawke’s Bay. The first stop after lunch was Apatu Farms.

Apatu Farms operates over 2,500 hectares, with approximately 1,000 hectares dedicated to vegetables including sweetcorn, pumpkins and onions supplying major processors and fresh markets. Other crops include wine grapes, and apples.

The farm faced significant agronomic challenges following cyclone flooding, which moved and deposited topsoil, silt, and debris across production areas. This introduced new pest and disease pressures requiring adapted management strategies. Frost management is addressed through strategically placed turbines and helicopters, with careful consideration of environmental and social impacts. The farm has adopted GPS-steered tractors, multi-row sprayers, and sophisticated management software.

A strict profitability standard drives decision-making, requiring each crop to be independently profitable including all costs – every crop must justify all costs including land lease. This led to discontinuing peas and other unprofitable crops. Labour management utilises local supervisors overseeing RSE scheme workers. Participants particularly appreciated the farm’s openness in sharing operational information.

The final host for the day was LandWISE Inc. where the group learnt about their science-backed approach using full-size equipment for trials rather than small research plots. Their work on minimal tillage, nitrogen testing protocols, and biodiversity through insectaries provided practical takeaways.

The final 20 minutes spent with a local vegetable grower to discuss local issues (harsh winters) and opportunities (milder summers enable superior spinach production) was highly appreciated.

DAY FIVE

Technology meets profitability

Our final farm visit was to Bayley Produce, a family-operated Hawke’s Bay business for more than 30 years. Tour participants were impressed with the large-scale, highly efficient operations producing summerfruit, pip fruit, melons, corn, strawberries, peas, and beans for domestic and export markets. We observed substantial investment in automation, including advanced packing lines, grading systems, and frost prevention technology – investment where it made economic sense. The operation’s sharp focus on profit margins and operational efficiency was evident.

In the field, participants were particularly interested in the innovative use of biodegradable film on beds to accelerate corn growth for early market access, providing competitive advantages while addressing environmental concerns as the material breaks down within six months.

Similar to what was discussed at Apatu Farms, here we also saw a strategic approach to resource efficiency and cost-benefit analysis, where crops that don’t deliver sufficient returns being discontinued. Growers also noted the flexible workforce model combining permanent local staff, contractors, and RSE scheme workers to manage labour-intensive operations across multiple crop types with varying harvest schedules.

Common ground

The New Zealand tour revealed that growers on both sides of the Tasman face many similar challenges. Workforce shortages, environmental pressures, tight profit margins, and pest management issues are universal concerns. Like Australian producers, New Zealand operations depend heavily on seasonal labour schemes – their RSE program mirrors our PALM scheme – to maintain viable operations.

What stood out was the innovative and disciplined fundamentals. The farming operations we visited demonstrated that profitability stems from a range of factors including sound business models, strategic crop rotations, commitment to quality, and efficient resource management all tailored to local conditions and farms. The tour offered valuable practical insights that some participating growers are already considering for their own operations.

Many thanks to all the farms and organisations who hosted us during the Tour and to Vegetables NZ for your support.