ATMAC European Study Tour: Sormac and Hessing Supervers

After arriving in Amsterdam late on Wednesday, the ATMAC European Study Tour visited on Thursday processing equipment manufacturer Sormac, as well as Hessing Supervers, one of the largest fresh produce processing facilities in Europe, and arguably the most advanced.

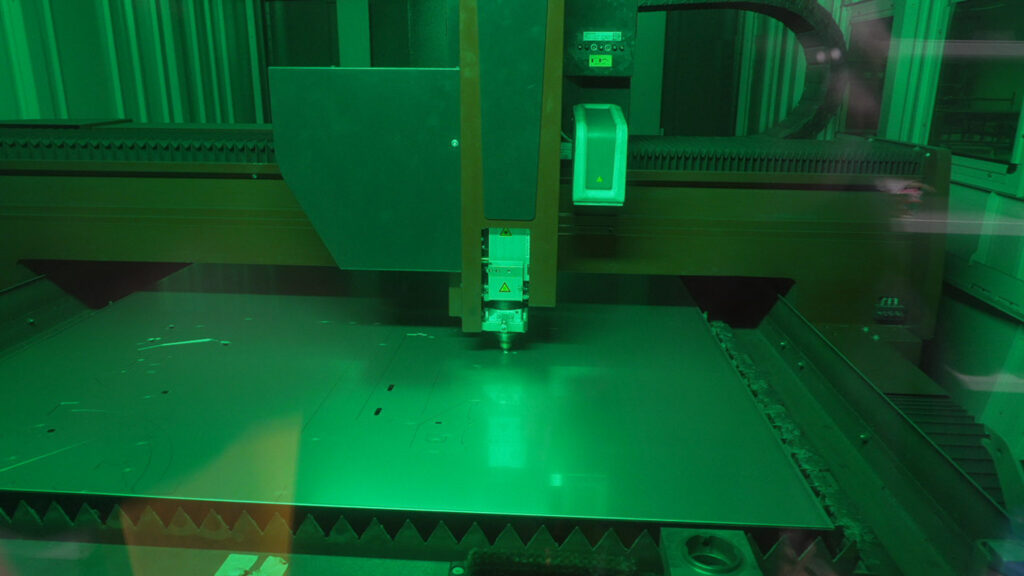

Located in Venlo in the Netherlands’ southeast, Sormac’s history goes back more than 100 years. The business specialises in fresh produce processing equipment, manufacturing everything in house from software to hardware, and has offices in the US and UK.

Australia is an important market for Sormac. Although consumption of processed produce is lower in Australia than the Netherlands or the UK, which are global leaders, Sormac nevertheless considers Australia one of the most developed markets for processing.

An increasing driver of Sormac’s R&D is automation. Between COVID-19 and the Russian invasion of Ukraine, which has reduced the previously large number of Ukrainians working in European processing operations, minimising the amount of labour and training required to operation processing equipment has been a key market demand, according to Sormac’s Area Sales Manager Lars Heuvelmans.

Maximising yield and shelf live of processed products are also key foci for the business, which has a dedicated research team working on continuous improvement of these areas.

The study tour also visited Hessing Supervers, a brand new processing facility just down the road from Sormac. Supervers (‘super fresh’) is the latest facility from Hessing, which is one of the top two processed produce suppliers for the insatiable Dutch market. Overall, Hessing produces around 7 million packs of processed fresh produce every week from its facilities across the Netherlands and Europe.

The Supervers facility is enormous at 62,000m2. While it’s still only 20 percent operational, it already employs 1,250 staff and processes 320 tonnes of raw materials every day, producing 5 million packages a week.

Undoubtedly one of the most advanced in the world, the scratch-build facility uses autonomous mobility vehicles that look like large robot vacuums to transport crates of product around the site, and robotic picking and sorting equipment.

While we weren’t able to take photos of the developing site, tour participants were amazed by the size and technology on display.